Description

If you’re seeking a reputable manufacturer and supplier of 50CrV4 sheets in Delhi and Ghaziabad, it’s essential to understand the material’s specifications, mechanical properties, applications, and available grades to make an informed decision.

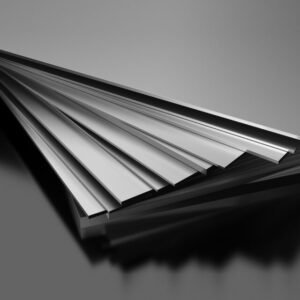

50CrV4 Steel Sheet Overview

50CrV4, also known as EN47, is a high-performance chromium-vanadium spring steel renowned for its exceptional toughness, shock resistance, and high fatigue strength when appropriately heat-treated. This alloy is widely utilized in applications demanding superior resilience and durability.

Chemical Composition

The chemical composition of 50CrV4 steel is as follows:

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.50 – 0.55 |

| Chromium (Cr) | 1.00 – 1.20 |

| Manganese (Mn) | 0.70 – 0.80 |

| Vanadium (V) | 0.15 – 0.25 |

| Silicon (Si) | 0.20 – 0.35 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.035 |

Source: A.M. Engineering Works

Mechanical Properties

50CrV4 steel exhibits the following mechanical properties:

| Property | Value |

|---|---|

| Tensile Strength | 800 – 1100 MPa |

| Yield Strength | ≥ 600 MPa |

| Elongation | ≥ 10% |

| Hardness | 248 – 302 HB |

Source: A.M. Engineering Works

Available Dimensions

50CrV4 sheets are available in various sizes to meet diverse application requirements. Common dimensions include:

| Thickness (mm) | Width (mm) | Length (mm) |

|---|---|---|

| 3.0 | 1170 | 2500 |

| 5.0 | 1180 | 2500 |

Source: A.M. Engineering Works

Applications

Due to its robust mechanical properties, 50CrV4 steel is utilized in numerous applications, including:

- Automotive components such as springs, fasteners, and transmission parts

- Aerospace engineering for high-stress components

- Heavy machinery parts like gears, shafts, and axles

- Oil and gas industry equipment requiring high pressure and fatigue resistance

Source: A.M. Engineering Works

Equivalent Grades

50CrV4 steel has several equivalent grades across different standards:

| Standard | Grade |

|---|---|

| DIN | 1.8159 |

| BS | 735A50 |

| SAE | 6150 |

| EN | 50Cr4V2 |

| JIS | SUP10 |

Source: A.M. Engineering Works

Heat Treatment

50CrV4 steel can undergo various heat treatment processes to enhance its properties:

- Annealing: Heat to 680-710°C, then cool slowly in the furnace.

- Hardening: Heat to 820-860°C, quench in oil.

- Tempering: Heat to 400-600°C, depending on the desired mechanical properties.

Source: A.M. Engineering Works

Finding Suppliers in Delhi and Ghaziabad

When searching for 50CrV4 steel sheet suppliers in Delhi and Ghaziabad, consider the following steps:

- Online Directories: Utilize industrial directories and B2B platforms to identify local suppliers.

- Industry Associations: Contact local steel industry associations for recommendations.

- Trade Shows: Attend regional trade shows and exhibitions to meet suppliers.

- Referrals: Seek referrals from industry peers who have experience with local suppliers.

Ensure that the chosen supplier provides material test certificates and complies with relevant quality standards to guarantee the authenticity and quality of the 50CrV4 steel sheets.

By understanding the specifications, properties, and applications of 50CrV4 steel sheets, you can make an informed decision when selecting a supplier in the Delhi and Ghaziabad regions.