Description

Open-Die Forging for Nitralloy 135 & 135M

What is Nitralloy 135 & 135M?

Nitralloy 135 and 135M are high-strength, alloy steels specifically designed for nitriding treatments, which create a hard, wear-resistant surface while maintaining a tough and ductile core. These grades contain controlled amounts of chromium, molybdenum, and aluminum, which form hard nitride layers during heat treatment. Their exceptional surface hardness, combined with fatigue and wear resistance, make them ideal for high-performance mechanical components.

When these materials are processed via open-die forging, the grain structure is refined and aligned, creating superior mechanical reliability and toughness—critical for demanding industries like oil & gas, aerospace, automotive, and heavy machinery.

Why Choose Open-Die Forging for Nitralloy 135 & 135M?

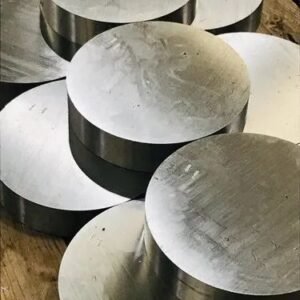

Open-die forging, unlike closed-die or casting, uses a series of compressive forces between flat dies to shape the material while maintaining an uninterrupted grain flow. At AM Engineering Works, we specialize in forging Nitralloy 135 and 135M into shafts, rings, blocks, and custom shapes.

Key benefits include:

-

Improved grain flow for enhanced fatigue and tensile strength.

-

Elimination of internal defects such as voids or porosity common in castings.

-

Better wear and impact resistance—essential for nitrided components.

-

Flexibility in producing large and custom-shaped components with minimal material waste.

-

Superior machinability and dimensional stability after heat treatment.

Mechanicalism: What Makes Nitralloy 135 & 135M Special?

The term “mechanicalism” here refers to the mechanical advantages and properties achieved through both alloy design and open-die forging.

Key Mechanical Properties (Post Heat-Treatment)

-

Surface hardness (after nitriding): Up to 1000–1100 HV (approx. 65–70 HRC).

-

Core hardness: Retains ductility and impact resistance, typically 300–400 HB.

-

High tensile strength: 930–1080 MPa (135 ksi range), depending on heat treatment.

-

Excellent wear resistance with minimal surface distortion during nitriding.

-

Good fatigue resistance: Perfect for high-cycle, dynamic load environments.

Grades of Nitralloy We Forge

The table below highlights the two primary grades:

| Grade | UNS Number | Key Alloying Elements | Applications | Typical Heat Treatment |

|---|---|---|---|---|

| Nitralloy 135 | G86150 | Cr, Mo, Al | Aerospace gears, crankshafts, precision machine parts | Nitriding after quench & temper |

| Nitralloy 135M | G86155 | Cr, Mo, Al, slight Ni | Oilfield drilling tools, shafts, and wear-resistant components | Gas nitriding or plasma nitriding for surface hardness |

AM Engineering Works: Expertise in Open-Die Forging

At AM Engineering Works, we offer end-to-end solutions for Nitralloy 135 & 135M:

1. Raw Material & Certification

We source high-quality billets or ingots that meet ASTM and AMS specifications. We ensure full chemical traceability and compliance with international standards.

2. Open-Die Forging Process

Our open-die presses and skilled forging team can handle weights from 100 kg to 20+ tons, producing:

-

Shafts & Step Shafts

-

Seamless Rings & Discs

-

Blocks & Rectangular Flats

-

Custom Preforms for machining

3. Heat Treatment

We perform normalizing, quenching & tempering, and nitriding pre-conditioning to prepare components for the hard nitriding layer while ensuring dimensional stability.

4. CNC Machining & Finishing

We offer rough and finish machining to your exact tolerances.

Learn more: CNC Machining Services

5. Inspection & NDT

-

UT (Ultrasonic Testing) for internal soundness.

-

MPI (Magnetic Particle Inspection) or DPI (Dye Penetrant Inspection) for surface quality.

-

Hardness and microstructure tests for nitriding readiness.

Applications of Nitralloy 135 & 135M Forgings

-

Aerospace components: Landing gear parts, gears, and wear-resistant surfaces.

-

Oil & gas industry: Drill collars, tool joints, and wear sleeves.

-

Automotive: High-performance crankshafts, camshafts, and transmission components.

-

Heavy machinery: Shafts, spindles, and rollers requiring surface wear resistance.

-

Industrial tools: Dies, molds, and other precision parts benefiting from nitrided surfaces.

Heat Treatment & Nitriding

Pre-Nitriding Heat Treatment

Forgings are quenched and tempered to the desired core hardness (approx. 300–400 HB).

Gas or Plasma Nitriding

Nitriding introduces nitrogen into the steel surface at 500–550°C, forming hard nitride layers without dimensional distortion. The result is extreme surface hardness with a ductile, shock-resistant core.

Advantages of AM Engineering Works in Nitralloy Forgings

-

Customized forging sizes: Shafts up to 12m, rings up to 3m OD, and heavy blocks.

-

Integrated heat treatment and machining to reduce lead times.

-

Global standard compliance: ASTM, AMS, and API standards.

-

Engineering expertise: We recommend the best forging reduction ratios and heat treatment cycles for optimal properties.

-

On-time deliveries: Quick Delivery Services

RFQ Checklist

When requesting a quote for Nitralloy 135 or 135M open-die forgings, provide:

-

Material grade and specification (e.g., Nitralloy 135M AMS 6470).

-

Drawings and tolerances.

-

Heat treatment condition (e.g., pre-nitrided or annealed).

-

Surface hardness targets after nitriding.

-

Testing & certification needs (3.1/3.2, UT levels, hardness mapping).

-

Quantity and delivery schedules.

Internal Links for More Information

Why Choose AM Engineering Works?

AM Engineering Works has decades of experience producing precision-engineered open-die forgings in alloy and nitriding steels. With state-of-the-art equipment, metallurgical expertise, and integrated heat-treatment facilities, we ensure every forging meets international quality standards and exceeds customer expectations.

Conclusion

Nitralloy 135 and 135M open-die forgings are the go-to choice for high-wear, high-fatigue, and high-performance applications. With our end-to-end manufacturing capabilities—forging, heat treatment, machining, and testing—we deliver reliable, ready-to-install forgings tailored to your needs.